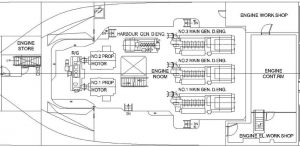

MACHINERY PART

The propulsion equipment can be monitored and operated at the bridge control navigation console on the bridge, the engine control room console and the propulsion motor control panel in the engine room.

A pair of propulsion motors are equipped as a propulsion plant. The controllable pitch propeller is driven by these propulsion motors whose rotation is changeable between two speed modes. The electric power is supplied from three main generators and one harbor generator to the motors.

Propeller and rudder

Propulsion motors

Main generator engines

Bow thruster

Principal Particulars of Machinery Part

| Propulsion motor (NISHISHIBA) 1000/300 kW, two speed modes | 2 sets |

| Propeller(KAMOME) Controllable pitch propeller 4 blades | 1 set |

| Main generator(YANMAR) 1300 kW × 900 min-1 | 3 sets |

| Harbor generator(YANMAR) 530 kW × 1200 min-1 | 1 set |

| Reduction gear (HITACHI NICO) | 1 set |

| Bow thruster(KAMOME) Controllable pitch propeller type | 1 set |

| Main air compressor(SANWA) 30 m3/h × 1800 min-1 | 2 sets |

| Fresh water generator(SASAKURA) Reverse osmosis type 20 t/day 1 | 1 set |

| Fresh water generator(SASAKURA) Vacuum evaporation type 5 t/day | 1 set |

| Incinerator(SUNFLAME) 360 kW | 1 set |

| Stern tube sealing(KEMEL) | 1 unit |

MACHINERY AUTOMATION SYSTEM

1. Safety operation and man-power saving

To reduce the engineers’ workload, the engine room is equipped with the latest facilities, which satisfy the requirements of the Japanese government. The propulsion motors and controllable pitch propeller are controllable from the bridge control console on the bridge and the engine control room console in the engine control room. ON-OFF control of auxiliary pumps and valves is also possible remotely from engine control room console. Color LCD panels enable monitoring of temperature, pressure, liquid level, etc.

Engine control room console

Main switchboard

2. Total control system(TCS)

The total control system is composed of ON-OFF control of generator engines and auxiliary pumps in each mode by sequence control. This system is installed in the engine control room console mentioned above and makes easy sequence control by using color LCD touch-panels on the console.

Main generator watch system

Engine control room

Total control system

3. SPARE PARTS MANAGEMENT SYSTEM

A spare parts management system is provided in order to keep equipment in good condition and rationalization of maintaining and managing various equipment. This system performs management of loading and delivery of spare parts and their store places, and produces purchasing slips.